1 - Foundry / Melting

A foundry is a place where metals are cast into shapes by melting them into a liquid, pouring the metal in a mold, and removing the mold material or casting after the metal has solidified as it cools. In this process, parts of desired shapes and sizes can be formed.

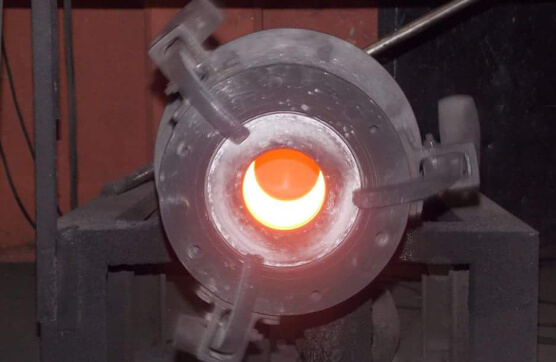

2 – Centrifugal Casting

We use centrifugal casting or rotocasting technique to cast thin-walled cylinders. it is needed to attain results of high quality, particularly for precise control of their metallurgy and crystal structure. In this technique, a permanent mold is rotated continuously about its axis at high speeds of 3000 rpm as the melted metal is poured. The melted metal is centrifugally thrown towards the inside mold wall, where it solidifies after cooling. Impurities and inclusions are thrown to the surface of the inner diameter, which can be machined away.

3 - Lathe Machining

A lathe is a machine tool which rotates the workpiece on its axis to perform various operations such as cutting, facing and turning, with tools that are applied to the workpiece to create an desired object. The job can be held in place by one, at least one of which can be moved horizontally to accommodate varying material lengths. To achieve this refined products we have a highly skilled work force.

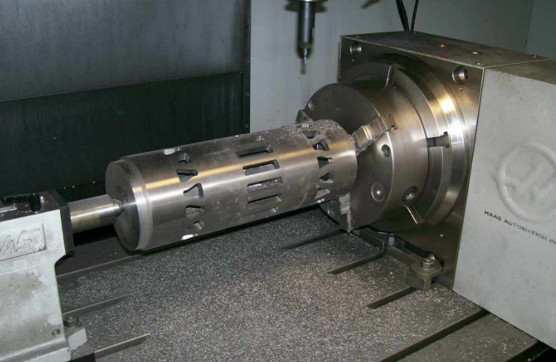

4 - CNC Machining

Surfaces that require tight dimensional control are machined. Many castings are machined in CNC milling centers. CNC lathes use computers and servomechanisms to regulate the rates of movement. The reason for this is to have better dimensional capability and repeatability than many casting processes. More and more the process of finishing a casting is being achieved using robotic machines which eliminate the need for a human to physically grind or feed.

5 - Honeing

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but may also improve the surface texture.

6 - Grinding

Any situation in which extremely precise metalworking is required, the cylindrical grinder is able to provide a level of precision unlike any other machine tool. From the automotive industry, the benefits the cylindrical grinder have given us are immeasurable.

7 - Inspection

We have invested in equipments like Special Gauges, Roughness Tester, Slip Gauges, Height Gauges, Ferro lab, Metallurgical Microscope, Spectrometer from Spectromaxx Germany and Profile Projector etc to help our QA team do the best. On-site Spectrometer helps us maintain our chemical composition for each casting batch conforming to the I.S.S., B.S.S. or ASTM specifications provided by our customers. We also have a state of the art Laser-Marking machine to facilitate proper part marking & identification.

8 - Packaging & Shipping

The cast parts are then removed from the runner system by cut-off wheel or conventional engineering methods.